Primarily, manufacturers use intelligent cameras to make use of machine vision when it comes to inspection. This allows the crooks to have a large amount of benefits. For instance, they could take pleasure in the automation of task, easy integration and expense reduction. If you want to choose this sort of machine, be sure you look at the following things first. This should help you make the best choice.

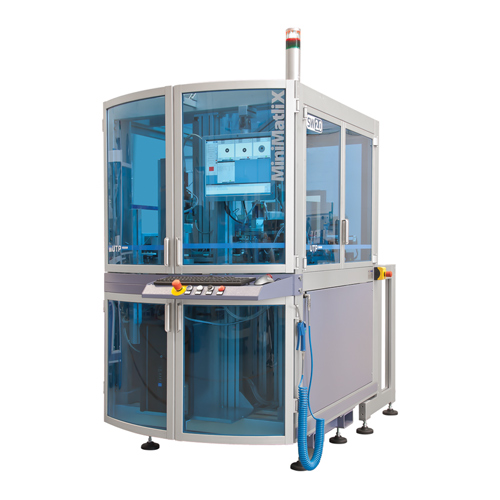

Systems Integration

The machine you decide on should contain high-quality photoelectric sensors. These sensors perform automated inspection and process the photos of the products. Actually, an excellent unit posesses a large amount of cameras like progressive scan cameras, cameras, and analog cameras. Determined by your business, you can choose from the three kinds of cameras.

Software Features

Given listed below are some software features that your vision inspection system should have. These characteristics are very important for a lot of reasons.

Object Tools: Power tools in the machine will assist you to do the inspection of the products stated in your production unit. They’ll analyze the shapes to determine the geometric characteristics like the density, perimeter, and size. If you need to scan and locate the components, your machine should have this selection.

OCR Tools: OCR tools derive from a technology that could scan and verify mechanically generated or printed characters. These power tools can see serial numbers and identification numbers. This method is so powerful that it could read severely damaged markings.

Calibration: Ideally, up your eyes inspection system should have calibration tools which will turn pixel coordinates into actual coordinates.

Data Analysis: With these tools, your machine can analyze leads to the tubular format. These results provides information concerning the inspection along with the image.

Matching: These tools can identify similar patterns of various images. These patterns are classified as grayscale pattern matching.

Gauging: They are measurement tools in the machine vision system.

Help: Ideally, your machine vision system will happen with tutorial guides. These guides needs to be clear to see to help you refer to the instructions while operating it.

Application of a Vision Inspection System

If one makes computer chips, you need a vision inspection system to determine the epoxy. And that means you need to inspect different package types. For this reason, you have to access and save a lot of inspection files.

The inspection system can get the acceptance level. Moreover, the inspection results should provide at the very least four-sided independent results. Besides, the system should figure out the epoxy length in the image. In other words, it must capture the positioning, area and width accurately.

The I/O in the inspection system should support the host equipment. Lastly, you might go with a system which allows customization depending on your environment.

The Takeaway

In a nutshell, the machine vision strategy is the state-of-the-art imaging technology that enables accurate inspection. Ensure you select the best cameras to capture and analyze the necessary images with the help of the very best software. This is important to streamline the product quality control processes in a joyful manner.

More information about KEYS go to our new web page.